New Delhi : Vedanta Aluminium Business, India’s largest producer of the aluminium and value-added products, has bagged topspots at Perform, Achieve and Trade (PAT) Cycle-II among the Indian Aluminium Industry. Perform Achieve and Trade (PAT) scheme is a regulatory instrument deployed by the Ministry of Power, Government of India, to reduce specific energy consumption in energy intensive industries with an associated market-based mechanism to enhance cost effectiveness through certification of excess energy savings, which can be traded.

Among Aluminium Smelters in India, Vedanta’s subsidiary Bharat Aluminium Company (BALCO) secured the coveted top spot with the highest Energy Saving Certificates, followed by Vedanta Jharsuguda’s Smelter I. Vedanta’s Alumina Refinery at Lanjigarh, ranked highest among peer alumina producers. An alumina refinery is a plant where bauxite is refined into aluminium oxide or alumina, and an aluminium smelter is a plant where aluminium is produced from alumina. These achievements bear testimony to Vedanta Aluminium’s robust endeavours towards energy conservation for business and environment sustainability.

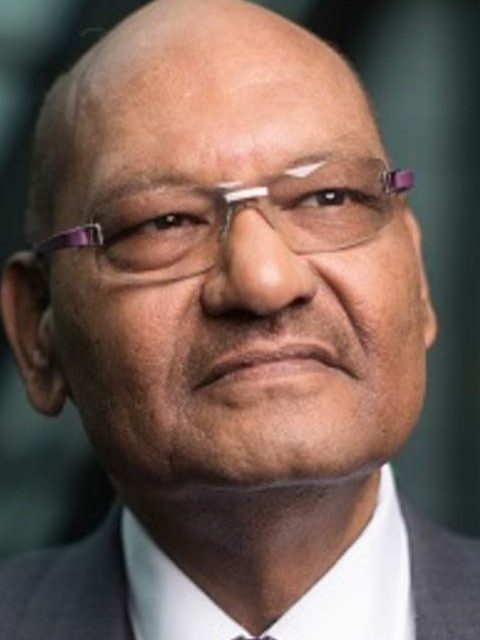

Speaking about Vedanta’s energy stewardship, Rahul Sharma, CEO – Vedanta Aluminium Business, said, “Being India’s largest aluminium producer, our aim at Vedanta Aluminium is to be the best in all facets of business, including Environment, Social and Governance (ESG) sustainability. Maximising energy conservation and minimising carbon footprint are two key pillars of our sustainable business development agenda. A three-pronged strategy of ensuring judicious resource usage, energy-efficient operations, and renewable energy sourcing, helps us further our energy sustainability and climate action goals. Towards this, we have adopted global best-practises in energy and resource management, and deployedcutting-edge solutions to reduce our carbon footprint.”

Energy management is at the heart of Vedanta Aluminium’s climate action roadmap, andfinds realization throughdedicated efforts towardsattaining highest operational efficiency of assets and processes.These include impactful initiatives for optimisation of specific energy consumption in production processes and a long-term focus on migrating to low carbon energy mix.

Prafulla Behera, Site In-Charge of IGSEC Heavy Engineering Limited, which is the Operations & Maintenance partner for Power Plant at Lanjigarh, adds, “Withour engineering and domain expertise, we have been working with Vedanta on their energy efficiency and energy sustainability targets. We are proud to be playing a crucial role in Vedanta’s journey towards being a forerunner in the field of energy conservation and ensuring maximum energy optimization at its world-class refinery operations.”